Relays: The Versatile Switches in the World of Electronics

10/25/2024 11:32:17 AM

Relays are essential components in the vast and intricate domain of electronics, serving as reliable and versatile switches that control the flow of electrical current in a wide variety of applications. From simple household appliances to complex industrial control systems and critical automotive and aerospace technologies, relays play a crucial role in enabling the automation, protection, and efficient operation of electrical circuits.

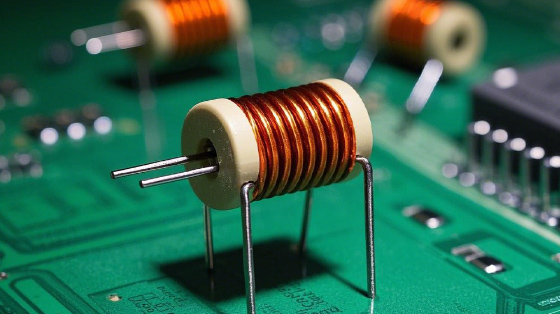

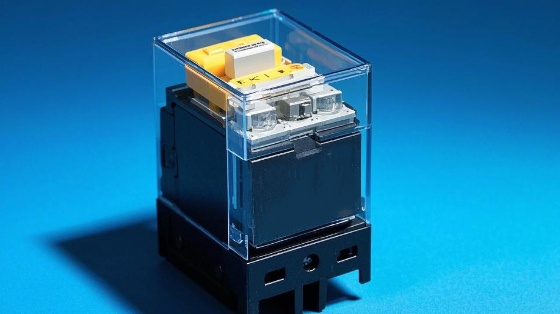

At its core, a relay is an electrically operated switch. It consists of an electromagnet and a set of contacts. When an electric current is passed through the electromagnet, it generates a magnetic field. This magnetic field attracts a movable armature, which in turn causes the contacts to either close or open, depending on the design of the relay. There are two main types of contacts: normally open (NO) and normally closed (NC). In a normally open relay, the contacts are open when the electromagnet is not energized, and they close when the electromagnet is activated. Conversely, in a normally closed relay, the contacts are closed when the electromagnet is not energized and open when the electromagnet is activated.

One of the most common applications of relays is in power control and switching. In household appliances such as refrigerators, washing machines, and air conditioners, relays are used to control the operation of various components. For example, in a refrigerator, a relay may be used to switch the compressor motor on and off, depending on the temperature inside the refrigerator. The thermostat senses the temperature and sends a signal to the relay. When the temperature rises above a certain set point, the relay energizes the electromagnet, closing the contacts and allowing current to flow to the compressor motor, which then starts cooling the refrigerator. In industrial settings, relays are used in motor control circuits. They can be used to start, stop, and reverse the direction of large motors. For instance, in a manufacturing plant, a relay panel may be used to control a bank of motors used in conveyor belts, pumps, and other machinery. By using relays, the control of these motors can be centralized and automated, improving the efficiency and safety of the industrial process.

Relays also play a significant role in electrical protection systems. In power distribution systems, overcurrent relays are used to detect excessive current flow and protect the circuit from damage. When the current exceeds a predetermined value, the overcurrent relay trips, opening the contacts and disconnecting the circuit. This helps to prevent overheating of wires, damage to electrical equipment, and the risk of electrical fires. Another type of protection relay is the differential relay. It is used to protect transformers, generators, and other large electrical assets. The differential relay compares the current entering and leaving a protected device. If there is a significant difference between the two currents, which could indicate an internal fault such as a short circuit or a ground fault, the relay trips and isolates the faulty device from the rest of the system.

In automotive applications, relays are used for a multitude of functions. They are used in the starting system, where a starter relay is used to connect the battery to the starter motor. When the ignition key is turned, a small current is sent to the starter relay, which then closes the contacts and allows a large current to flow to the starter motor, cranking the engine. Relays are also used in the lighting system, controlling the headlights, taillights, and other lights. For example, a relay may be used to switch between high and low beam headlights. In addition, relays are used in the automotive control modules, such as the engine control unit (ECU) and the body control module (BCM). These modules use relays to control various actuators and sensors in the vehicle, such as fuel injectors, solenoids, and switches.

The performance of relays is determined by several key factors. One of the most important is the contact rating. This includes the maximum current and voltage that the contacts can handle without arcing or overheating. For example, a relay used in a high-power industrial motor control circuit may have a contact rating of several hundred amps and thousands of volts, while a relay used in a low-power household appliance may have a much lower contact rating. The switching speed of the relay is also a crucial factor. Some applications require fast switching, such as in high-frequency circuits or in applications where rapid response is needed. However, faster switching speeds can also lead to increased wear and tear on the contacts. The life expectancy of the relay is another important consideration. It depends on factors such as the number of switching cycles, the current and voltage levels, and the environmental conditions. In harsh environments, such as in industrial or automotive applications where there may be vibration, temperature extremes, and dust, the relay must be designed to withstand these conditions and still maintain its reliability over a long period.

As technology advances, relays are also evolving to meet new challenges and requirements. Miniaturization is a significant trend, especially in the electronics industry where space is often at a premium. Miniaturized relays are being developed for use in portable electronic devices, such as smartphones, tablets, and wearable devices. These relays are designed to be smaller in size while still maintaining their switching performance. Another trend is the improvement of relay reliability. New materials and manufacturing processes are being explored to reduce contact wear, improve insulation, and enhance the overall durability of relays. For example, the use of silver-tin oxide (AgSnO2) contacts instead of traditional silver-nickel (AgNi) contacts can reduce arcing and improve the life expectancy of the relay. In addition, advanced manufacturing techniques such as laser welding and precision molding are being used to improve the quality and consistency of relay production.

The integration of relays with other electronic components and systems is also becoming more common. In smart grid applications, relays are being integrated with sensors and communication modules to enable more intelligent power distribution and control. For example, a smart relay may be able to monitor the power quality, detect faults, and communicate with a central control station in real-time. In industrial automation, relays are being integrated with programmable logic controllers (PLCs) and other control systems to provide more flexible and efficient control of industrial processes. This integration allows for more complex control algorithms and better coordination between different components of the system.

In conclusion, relays are the versatile switches that form the backbone of many electrical circuits and systems. Their wide range of applications, from power control and protection to automotive and industrial automation, highlights their importance in the world of electronics. As technology continues to progress, relays will continue to evolve, adapting to new challenges and enabling more advanced and efficient electronic systems.