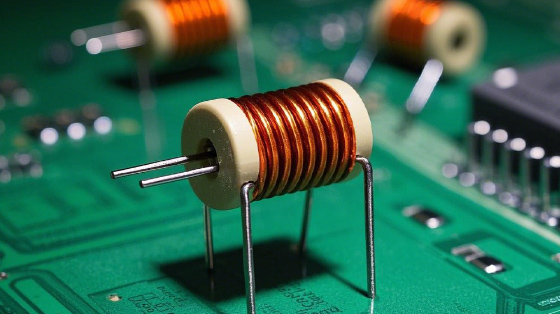

In the complex and interconnected world of electronics, circuit protection components stand as the vigilant guardians, ensuring the integrity and reliability of electrical circuits. These unassuming yet crucial elements play a pivotal role in preventing damage to sensitive electronic devices and systems from overvoltage, overcurrent, electrostatic discharge (ESD), and other electrical hazards. From the smallest handheld gadgets to large-scale industrial installations and critical infrastructure, circuit protection is the first line of defense against potential failures and disasters.

One of the most fundamental types of circuit protection devices is the fuse. A fuse is a simple yet effective component that consists of a metal wire or strip with a low melting point. When the current flowing through the circuit exceeds the rated value of the fuse, the excessive heat generated causes the metal to melt, thereby interrupting the circuit and preventing further damage. Fuses are available in various ratings and sizes, depending on the specific application requirements. For example, in a household electrical circuit, a standard fuse with a relatively low current rating is used to protect against short circuits and overloads. In contrast, in industrial settings where higher currents are involved, larger and more robust fuses are employed. The advantage of fuses lies in their simplicity and reliability. Once a fuse has blown, it provides a clear indication that there has been an overcurrent event, making it easy to identify and replace. However, they are a one-time protection device and need to be replaced after each activation.

Another widely used circuit protection device is the circuit breaker. Unlike a fuse, a circuit breaker can be reset after it trips. It operates based on the principle of electromechanical or electronic sensing of overcurrent conditions. When an overcurrent occurs, a trip mechanism is activated, which opens the circuit contacts and interrupts the flow of current. Circuit breakers are commonly used in residential, commercial, and industrial power distribution systems. They offer the convenience of being able to be reset, eliminating the need for frequent replacement as in the case of fuses. Moreover, modern circuit breakers often incorporate additional features such as ground fault protection and arc fault protection. Ground fault circuit breakers (GFCBs) are designed to protect against electrical shock hazards by detecting leakage currents to the ground. Arc fault circuit breakers (AFCBs) are capable of detecting and interrupting dangerous arcing conditions that can occur in electrical wiring, reducing the risk of electrical fires.

Surge protectors are essential in protecting electronic equipment from transient voltage spikes, which can be caused by lightning strikes, power grid fluctuations, or switching operations. A surge protector typically contains metal oxide varistors (MOVs) or other voltage clamping devices. When a surge voltage exceeds a certain threshold, the MOVs conduct and divert the excess energy to the ground, thereby protecting the connected devices from damage. Surge protectors are commonly used in computer systems, telecommunications equipment, and home entertainment systems. For instance, in a computer network, a surge protector installed at the power inlet and data lines helps safeguard the routers, switches, and servers from power surges that could otherwise corrupt data or damage the sensitive electronic components. In addition to power line surge protectors, there are also surge protection devices for data lines, such as Ethernet ports and telephone lines, to protect against surges that may enter through these communication channels.

Overvoltage protection diodes, such as transient voltage suppressor (TVS) diodes, are another important class of circuit protection components. TVS diodes have a very fast response time and are designed to clamp the voltage at a safe level when a transient overvoltage occurs. They are widely used in sensitive electronic circuits, such as microcontroller-based systems, where even a brief overvoltage spike can cause permanent damage to the integrated circuits. For example, in a smartphone's charging circuit, TVS diodes are used to protect the charging IC and the battery from voltage spikes that may occur during the charging process. These diodes can handle high peak power dissipation and are available in a variety of voltage ratings to match the specific protection requirements of different circuits.

In addition to protecting against overcurrent and overvoltage, electrostatic discharge (ESD) protection is crucial in modern electronics. ESD events can occur when a charged object comes into contact with an electronic device, causing a sudden flow of electrostatic charge. ESD protection devices, such as ESD diodes and varistors, are designed to shunt the ESD current away from sensitive components and prevent damage. These devices are commonly integrated into IC packages or used on circuit boards near connectors and other areas where ESD is likely to occur. For example, in a laptop's keyboard interface, ESD protection diodes are used to protect the motherboard circuitry from ESD generated by the user's touch. In manufacturing environments, where electronic components are handled and assembled, proper ESD protection measures, including the use of ESD wrist straps and floor mats in addition to ESD protection devices, are essential to prevent damage to the components during production and assembly.

The design and selection of circuit protection components depend on several factors, including the nature of the electrical circuit, the expected voltage and current levels, the frequency of operation, and the environment in which the circuit operates. For example, in a high-frequency circuit, the parasitic capacitance and inductance of the protection device can affect the circuit's performance, so specialized high-frequency protection components with low parasitic effects need to be used. In a harsh industrial environment, where there may be high levels of electromagnetic interference (EMI) and mechanical vibrations, the circuit protection devices need to have robust packaging and EMI shielding. Moreover, in some applications, such as aerospace and military systems, where reliability is of utmost importance, redundant circuit protection schemes may be employed to ensure continuous operation even in the event of a single component failure.

As technology continues to advance, the demands on circuit protection are also evolving. With the increasing use of renewable energy sources, such as solar and wind power, and the growth of the Internet of Things (IoT), new challenges and opportunities arise. In renewable energy systems, circuit protection needs to handle the unique characteristics of the power generated, such as variable voltage and frequency in wind turbines and the need for maximum power point tracking in solar panels. In IoT devices, which are often battery-powered and have limited space, miniaturized and low-power circuit protection components are required. Additionally, the development of new semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), offers the potential for more efficient and compact circuit protection devices. These materials have higher breakdown voltages and faster switching speeds compared to traditional silicon, enabling the design of smaller and more powerful protection components for high-voltage and high-power applications.

In conclusion, circuit protection is an essential aspect of modern electronics, safeguarding the integrity and functionality of electrical circuits and systems. The diverse range of circuit protection devices, from fuses and circuit breakers to surge protectors and ESD protection components, provides comprehensive protection against various electrical hazards. As technology progresses, continuous innovation in circuit protection will be necessary to meet the evolving demands of new applications and ensure the reliable operation of electronic devices in an increasingly complex and electrically challenging environment.