In the vast and intricate realm of electronic circuitry, inductors, coils, and chokes play a fundamental and often underappreciated role. These magnetic components are essential building blocks that enable the manipulation and control of electrical energy in a variety of ways, from filtering and energy storage to impedance matching and electromagnetic interference (EMI) suppression. Their unique properties and functions are integral to the proper operation of countless electronic devices and systems, ranging from power supplies and audio equipment to wireless communication devices and automotive electronics.

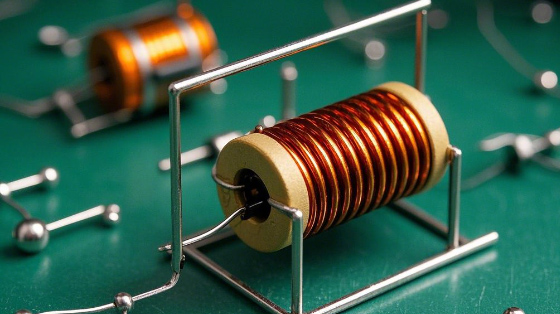

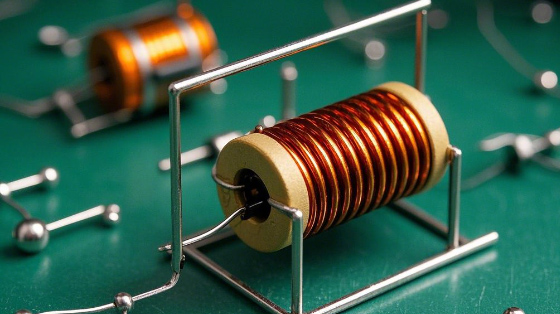

An inductor is a passive electronic component that stores energy in a magnetic field when an electric current passes through it. It is typically composed of a wire wound into a coil, often around a core made of a magnetic material such as iron, ferrite, or powdered iron. The basic principle behind an inductor's operation is Faraday's law of electromagnetic induction, which states that a changing magnetic field induces an electromotive force (EMF) in a conductor. When the current through an inductor changes, the magnetic field around it also changes, and this induces a voltage across the inductor that opposes the change in current. This property, known as inductance, is measured in henries (H) and determines the amount of energy that can be stored in the magnetic field of the inductor.

Inductors find extensive use in power supply circuits. In a simple DC-DC converter, for example, an inductor is used in conjunction with a switching transistor and a capacitor to step up or step down the voltage. During the switching cycle, the inductor stores energy when the transistor is on and releases it when the transistor is off, transferring energy from the input to the output and smoothing the voltage waveform. Inductors also play a crucial role in EMI filtering. In power supply circuits and other electronic systems, unwanted high-frequency noise can be generated and propagated through the power lines and other conductors. By placing an inductor in series with the power line or signal path, the high-frequency noise can be attenuated. The inductor presents a high impedance to high-frequency signals, effectively blocking them from reaching sensitive components downstream. This helps to improve the overall electromagnetic compatibility (EMC) of the system and prevent interference with other nearby electronic devices.

Coils are closely related to inductors and are often used interchangeably in some contexts. However, coils can have a more general meaning and may refer to any wound wire configuration, not necessarily one that is optimized for its inductance properties. In some applications, coils are used for their magnetic field generation capabilities rather than their inductance. For example, in electromagnets, a coil of wire is wound around a ferromagnetic core. When a current is passed through the coil, a strong magnetic field is generated. Electromagnets are used in a wide range of applications, from industrial lifting and sorting equipment to magnetic resonance imaging (MRI) machines in the medical field. In an MRI machine, a powerful electromagnet is used to create a uniform and stable magnetic field that allows for the imaging of internal body structures by detecting the interaction of the magnetic field with the protons in the body's tissues.

Chokes are a specific type of inductor that is designed primarily for the purpose of blocking or attenuating alternating current (AC) signals while allowing direct current (DC) to pass relatively unimpeded. They are often used in power supply circuits to filter out AC ripple. In a rectifier circuit, which converts AC power to DC power, the output of the rectifier still contains a significant amount of AC ripple. By placing a choke in series with the output of the rectifier and following it with a capacitor, the choke and capacitor form a low-pass filter that effectively removes the AC ripple, providing a smoother DC output. Chokes are also used in audio circuits to separate the audio signal from the power supply. In an audio amplifier, for example, a choke can be used to prevent the AC power supply noise from coupling into the audio signal path, thereby improving the sound quality and reducing hum and other unwanted noise.

The performance of inductors, coils, and chokes is influenced by several factors. The number of turns in the winding, the diameter of the wire, the core material, and the physical size and shape of the component all play a role in determining its inductance, resistance, and other electrical characteristics. For example, increasing the number of turns in a coil generally increases its inductance, but it also increases the resistance of the wire, which can lead to power losses. The choice of core material is also critical. Ferromagnetic cores, such as iron or ferrite, can significantly increase the inductance of a coil compared to an air core, but they also introduce losses due to hysteresis and eddy currents. Different core materials have different magnetic properties, such as permeability and saturation flux density, which need to be carefully considered depending on the application requirements.

As technology advances, the demands on inductors, coils, and chokes are evolving. In high-frequency applications, such as in wireless communication systems and high-speed digital circuits, the parasitic capacitance and resistance of these components become more significant. To meet the requirements of these applications, new designs and materials are being developed. For example, multilayer ceramic chip inductors have been developed for surface mount applications in high-frequency circuits. These inductors have a small form factor and low parasitic capacitance, making them suitable for use in miniaturized electronic devices such as smartphones and tablets. In addition, new magnetic materials with improved high-frequency characteristics, such as soft ferrites with high resistivity, are being used to reduce eddy current losses in high-frequency inductors.

The miniaturization trend in electronics also poses challenges and opportunities for inductors, coils, and chokes. As electronic devices become smaller and more compact, there is a need for smaller-sized magnetic components without sacrificing performance. This has led to the development of microinductors and integrated magnetic components. Microinductors are fabricated using advanced microfabrication techniques, similar to those used in semiconductor manufacturing. They can be integrated with other components on a single chip, reducing the overall size and improving the performance of the system. Integrated magnetic components combine the functions of inductors, transformers, and other magnetic elements in a single package, further simplifying the circuit design and reducing the number of external components.

In conclusion, inductors, coils, and chokes are the magnetic backbone of electronic circuits, providing essential functions such as energy storage, filtering, and impedance matching. Their diverse applications and continuous technological evolution make them a crucial part of the modern electronics landscape. As research and development efforts continue to address the challenges and explore new opportunities, these magnetic components will continue to play a vital role in enabling the next generation of smaller, faster, and more efficient electronic devices and systems.